What did 125+ injured workers say at the release of CRUSHED2021?

- Safe in India

- Feb 17, 2022

- 6 min read

Updated: Jul 5, 2024

On 26th January 2022, we released the third annual sequel of our worker accident prevention report - CRUSHED2021 – based on information from 2.500+ workers injured in the auto-sector and assisted by us. The online event was attended by 125+ injured workers from 11 different locations in Haryana and by another 280+ participants from across the globe.

We shared some of the findings of CRUSHED2021 and requested these workers to talk about them. 1. How many of you were injured in the auto component factories? (Report finding: 80%+). This is what they said from Aliyar, Bawal, Binola, Dharuhera, Gouchi, Jawahar Colony, Kadipur, Kasan, Manesar, Naharpur, Sohna Chowk:

2. Why are there so many and so bad accidents on power presses? (Report findings: 50%+ on power presses; 1.97 fingers lost per crush injury - half a finger more than other machines, and 2x probability of losing fingers on power presses compared to other machines)

“Machines are presented along with safety equipment only during audits. Checklist, gloves etc. are given. After that, they take them back”.

- Santosh Srivastav, an injured worker

"केवल मशीनों के ऑडिट के दौरान सुरक्षा उपकरण जैसे चेकलिस्ट, दस्ताने आदि दिए जाते हैंI ऑडिट के बाद उन्हें वापस ले लिया जाता है।"

-संतोष श्रीवास्तव, चोटग्रस्त श्रमिक

3. Does your machine have proper maintenance? Who does it? Do they listen to you? (Report finding: 85% not inspected daily; 88% without safety sensors; 48% injured workers identified problems with machine before the accident and were not heard)

"Maintenance means the machine should be checked everyday in the morning, but no one comes to check it, they only check when it has some issue or accident happens on it"

- Ranjit, an injured worker

"मेंटेनेंस का मतलब है कि मशीन को हर रोज सुबह चेक किया जाना चाहिए, लेकिन कोई भी इसे चेक करने नहीं आता है, वे केवल तभी चेक करते हैं जब इसमें कोई समस्या होती है या उस पर दुर्घटना होती है"

- रंजीत, चोटग्रस्त श्रमिक

4. Are the laws related to power presses being followed? (Report finding: Most factories violate many extant regulations; potential criminal offences)

If we complain for safety then they say "'Go do whatever you can do, if you will cross your limits, we will get you killed"

-Arvind, an injured worker

"अगर हम सेफ्टी के लिए कंप्लेंट करते हैं तो वो कहते है "जा तुझ पर जो किआ जाए तू कर ले अगर ज़्यादा करेगा तो तुझे मरवा देंगे” -अरविन्द, चोटग्रस्त श्रमिक

5. What are the laws of power press being contravened? (Report Finding: Rampant violations including of Factory Act Sections 7A, 7B, 21, 24, 88, 88A; Punjab Factory Act Rules on Power Press 3,4,5,6,8; and IPC 287, 320)

Mr Kamal Jaswal, IAS (retd.), Former Secretary, Department of Information Technology, Government of India said

“Just as the diamond trade has resolved to reject blood diamonds, which are extracted in countries with a record of civil strife and human rights violation, the automotive industry helmed by OEMs should spurn the blood-stained auto parts produced by factories having a poor safety record”.

6. How did you learn to operate power press machine? (Report Finding: 95% not formally trained, almost all learnt on the job)

"First we assist for a while, then we learn by seeing and then they make us operators, they do not give any training."

- Mangesh, an injured worker

"पहले हम हेल्पर की तरह काम करते हैं, फिर हम देखते देखते सीख जाते हैं और फिर वे हमें ऑपरेटर बनाते हैं, वे कोई ट्रेनिंग नहीं देते हैं।"

-मंगेश, चोटग्रस्त श्रमिक

7. Is the 'training' being provided really appropriate/adequate? (Report finding: Quality of on the job training is poor)

Mr Dunu Roy, Director, Hazards Centre (IITD) said “A new parampara akin to that of the learning through heritage needs to be adapted and evolved for the current age of technology and the ever-changing nature of machines. We could teach the use of a 5 kg hammer in a family. The same cannot work for a 50-ton power press".

Highlights of findings of our report

The report was released by Mr Anil Swarup, IAS (retd), Former Secretary of Education, Former Coal Secretary, Government of India. He said “All CRUSHED 2021 recommendations are doable and can be implemented. Emotionally relatable, financially viable, politically acceptable, technologically feasible and administratively doable. SII needs to continue intensive dialogue with stakeholders. I am sure that the auto industry and government will respond positively to the recommendations”.

The report release received wide media coverage.

The Hindu "Three-fourth injured auto workers lost two fingers on an average: SII report"

ET Auto "Indian auto industry's dirty little secret : It doesn't care for its supply chain workers"

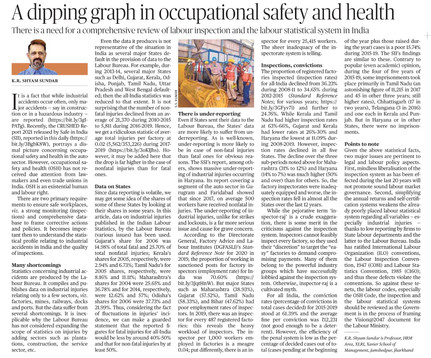

The Hindu "A dipping graph in occupational safety"

The Leaflet "Report on worker safety in Indian auto sector presents a despairing state of affairs"

The Wire "In NCR Industrial Heartland, Workers Continue to Lose Limbs, Livelihood in Auto Sector Mishaps"

The Frontline "Epidemic of injuries"

TOI Sunday Times Feature: "Your shiny new car may be built on crushed fingers"20 Feb22

Other media stories here

There are many other report findings we did not get the time to discuss at the release: Maruti-Suzuki, Hero, Honda suppliers remain largest contributors to accidents in Gurugram (93%) and Faridabad (75%). Bajaj, Eicher, JCB, Tata Motors, TVS, Yamaha suppliers are also significant contributors in Gurugram, Faridabad, Rudrapur, Neemrana. This is not just a small MSME problem: accidents in 22% of ACMA members (some of the largest factories/suppliers). Among the top three OEMs that SII has pursued since 2019, Maruti-Suzuki has taken the most initiative, with Honda and Hero lagging. Among the other seven of the top ten OEMs pursued from late 2020, Eicher and Hyundai have recently started engaging constructively. Ashok Leyland, Bajaj, Mahindra & Mahindra, Tata Motors, and TVS need to do better. SIAM and ACMA have also agreed a number of actions, such as a standard Supplier Code of Conduct for OEMs, a business case for safety, and the creation of OSH training materials for workers. ACMA has started some of these actions, albeit slowly, but SIAM needs to pick up pace. Haryana State reports only c.50 non-fatal injuries in Haryana (c.2% of national numbers) vs. c.500 reported just to SII every year since 2016. Central and Haryana State labor ministries have set up working groups based on SII reports but their outcome has not been made public yet. DG FASLI has agreed and started a few actions, including the first ever worker OSH training piloted with us. ISH-Gurugram has agreed to create a joint action “platform” including Maruti-Suzuki, Hero, Honda and SII, and which in its second meeting this year agreed to a few positive actions, such as safety assessments of an auto cluster. The MSME ministry has signed an MOU with SII for joint action. The BIS has formulated a panel to consider ISO standards for power press safety. For further details, we urge you to read the executive summary here

For full video of the event, please click here

So, what do you think and what can you do to help save thousands of Indian workers from these grave injuries and to help improve Indian labor productivity?

Would you ask your automobile dealer next time you buy a car, motorcycle, scooter, or even a tractor, a bus, a truck whether any worker lost his or her hands or fingers while making it?

If you are an auto-component manufacturer are you ready to improve safety for your workers because it has both human and business benefits? If you don’t believe that, please contact us and we will have explain to you how that is possible.

If you are a policy maker in the government, are you ready to implement the current law better? Are you willing to construct the new state rule under the new OSH&W Labor code to prevent these accidents and help improve the Indian labor productivity from its current dismal 115th ranking in the world?

At Safe in India, we will continue working towards improving worker safety in the auto-sector supply chain. We cannot do this alone; we need your support and guidance.

Have a safe and healthy 2022!

PS: Any donations before 31st March 2022 will receive match fundings from our strategic supporters from the batch of IIMA91: https://r.givind.org/Mmv2exBN

See all our supporters here

Comments